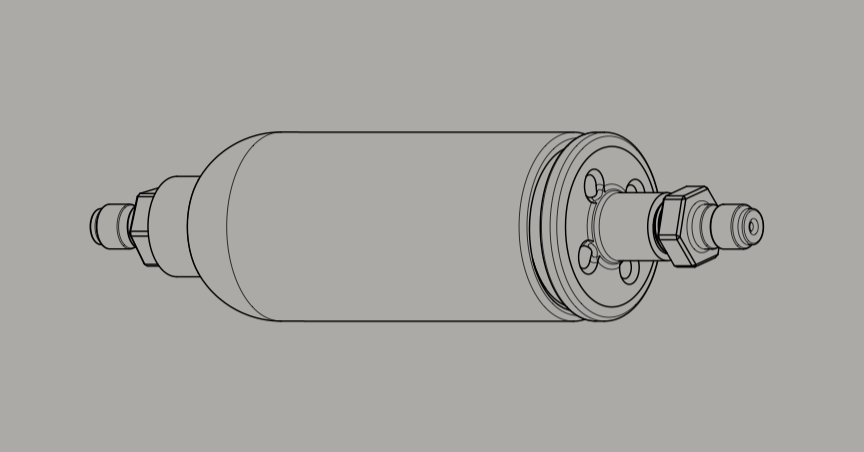

The Compression Stepping Valve is an innovative multi-stage pneumatic valve system designed to efficiently compress air to extremely high pressures, ranging from 5000 to 5500 psi, using either a manually operated pump or a low-pressure compressor system (up to 150 psi). Its advanced design leverages a series of compression stages, each equipped with precision-engineered chambers and check valves, to achieve superior air compression efficiency while maintaining user-friendly operation.

At the core of the system are high-strength steel alloy check valves that prevent backflow between stages, ensuring a one-way airflow for optimal performance. Each stage features progressively smaller chambers, which incrementally compress the air, starting from 150-200 psi and building up to the final pressure of 5500 psi. The chamber dimensions and compression ratios can be customized to adjust the input energy required, the number of compression stages, and the maximum pressure threshold.

The Compression Stepping Valve operates through a series of five stages:

This system’s operating principle relies on user input energy, either through manual pumping or a compatible shop air compressor, to push air through each compression stage. Its precision-engineered chambers and valves allow for consistent, repeatable compression cycles without requiring motors or additional pistons, making it highly efficient and reliable.

Safety is paramount in the Compression Stepping Valve’s design, with all components engineered to withstand four times the operating pressure at each stage. The valve is tested to a maximum pressure of 20,000 psi burst capacity, ensuring robust performance even under demanding conditions. Additional safety features include compatibility with pressure gauges to prevent overfilling and user-friendly operation for consistent air management.

This versatile system can be adapted for various applications by altering the chamber dimensions, number of stages, and compression ratios, making it suitable for high-pressure applications in fields such as PCP air rifles and other pneumatic systems. Its compact and efficient design redefines high-pressure air compression, delivering unmatched performance and reliability.

With calibers ranging from .177 to .30 and available barrel lengths of 600mm and 700mm, the IXWA delivers impressive performance metrics. It can achieve muzzle velocities of up to 1,000 fps with energy levels reaching 145 foot-pounds, depending on caliber and ammunition. The rifle’s design ensures a perfect balance of power, efficiency, and accuracy, making it an exceptional choice for target shooting, hunting, and tactical scenarios.

For advanced applications, the IXWA offers big bore configurations with expanded plenum size, increased magazine depth, and enhanced air reservoir capacity. These upgrades allow for even higher performance, with energy levels exceeding 500 foot-pounds in larger calibers such as .457. The IXWA air rifle sets a new standard in the industry by combining advanced engineering with user-focused design, making it a versatile and powerful tool for professionals and enthusiasts alike.